Products

AQUAFLO

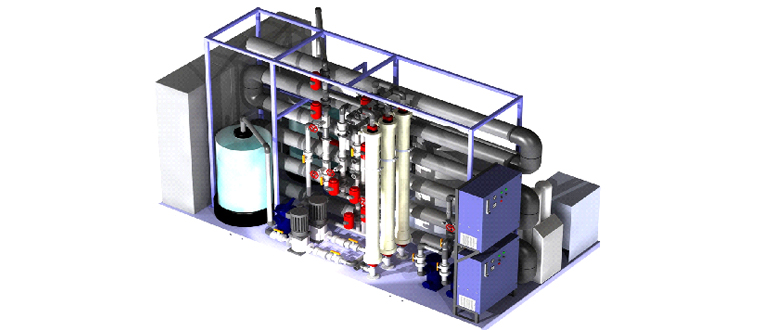

Aquatron Technologies Inc. has developed a highly efficient drinking water treatment plant technology that is certified to treat highly polluted water without the use of chemical products. Founded in 2002, Aquatron’s patented ozone/membrane-based water treatment technology removes the need for chemical processing and eliminates the toxic sludge by-product found in existing solutions. The very low fouling ozone membrane filtration module is an industry breakthrough that delivers significant treatment performance.

A Quebec government scientific committee has measured and confirmed Aquatron’s treatment performance as top tier in the market compared to large international competitors (Turbidity, color removal, Total Organic Carbon, etc.). Average annual plant availability reaches 95%, even considering initial plant stabilization periods. Water quality measured and independently reported to government regulatory bodies showed water quality 14 times better than the target norm (turbidity) even for the first plant deployed. Aquatron’s certified performance meets or surpasses international norms such as the US-EPA water standards.

The Aquatron process offers virtually stand-alone operation thanks to its chemical free and automated monitoring and control systems. It can substantially reduce 62% of typical operating costs by eliminating the need for expensive and toxic chemicals, sludge management and the specialized operators required to constantly adjust plant operations to varying raw water conditions. Aquatron’s plant operations self-adjust to maintain stable drinking water quality to customers. Aquatron’s highly scalable water plants are configured for remote surveillance through an Internet-based connection accessing a sophisticated process interface. Certified by local governmental authorities, water produced by Aquatron plants meets or exceeds international standards such as US-EPA norms. Aquatron’s water treatment solution is composed of three steps: Pre-filtration, Main filtration and treatment, and Disinfection.

AquaCAST is a highly effective, economical and odorless wastewater technology that generates up to 60% less sludge, has 30% lower energy/electricity consumption, and reduces greenhouse gas generation.

Through successful plant deployments in its local market, Aquatron has now proven its innovative treatment technology and is evaluating its strategic opportunities in the other markets. Aquatron seeks to accelerate market

penetration and leverage the growing market trend towards chemical free drinking water and advanced decentralized

waste water treatment.

- Prefabricated potable water treatment plants

- Skid-mounted or assembled on site (large flow rates)

- Easily scalable, modular design

- Ozone allows for minimal membrane fouling - Powerful,safe and green oxidant / disinfectant

- Fresh surface water or contaminated groundwater

- Markets: municipal, industrial, private infrastructures.

- New infrastructures and retrofit of existing systems

- General concept and value proposition “Plug and play” integration into existing infrastructure

- Complete water treatment train - without chemical products

- No sludge management or handling of toxic products

- No additional infrastructures for wastewaters

- “Intelligent” plant: manages treatment independently, automated operations, remote surveillance

- Ease of operation for local manpower

- Competitive pricing (Capital, operation and infrastructures)

- Performance certified by the Government of Canada/USA

- In line with sustainable development

- Leading technology with emerging contaminants (EDCs)

- Safe process

- No polymer adjustment

- No sludge produced

- 100% of wastewater can be returned directly to the environment

- Fully automated operation (PLC)

- Telemetric surveillance

- Treated water insensitive to fluctuations in raw water

- Simplified labour demands (30 min/day)

- Compact design

- High level of efficiency (85-90%)

- No chemicals

- No wastewater treatment plant required

Deminerization Systems

It is deionized water with an ion exchanging and Ozonization process or similar method. Demineralization unit is composed our patented technology using Ozone technology.

We are the only company in the world providing clean deminerize water for power generation plants without the use of any chemical and reducing operating cost to minimal. The Systems requires minimum or no change of filters for the systems. If RO system is employed, requires less frequent wash of the filter as the filter will be less foul due to clean and innovative technology.

Demineralization units run fully automatic as in all other treatment systems. Automation of these filters can be maintained in different ways and equipment. The whole unit can be remotely monitored and controlled. The structure of mineral tanks employed for systems is generally made up of carbon steel, stainless steel, polyglass, FRP, composite etc.

Automation of system can be achieved with a conductivity gauge to be fixed on system exit, besides time or volume control.

SEA SALT WATER SYSTEMS

Especially in the recent years, due to effect of global warming, fresh water amounts in the world have gradually been decreasing. Fresh water derivation from sea water by means of reverse osmosis method gains importance.

Treatment High Capacity Sea Water Reverse Osmosis Systems are used in

- Hotels

- Municipalities

- Building Estates

- Various Industries

Treatment Low Capacity Sea Water Reverse Osmosis Systems are used in

- Yachts

- Ro-Ro ships

- Military ships

- fishing boats

Sea water treatment systems are used in the treatment of waters up to TDS 50.000. It is possible to project models processing the consumption capacities starting from 100 m3/day to very high in one single body.

In the design of systems, full chemical analysis of water and design of pretreatment system is very significant. System is directed completely from a control panel. As an option, models can be equipped with automatic membrane washing system. Membrane external containers can be offered as PVC and stainless steel.

Aquatron`s technology for salt water treatment replaces the traditional ultrafiltration stage in the desalinization process train. Pretreating with Aquatron offers the core value propositions of the technology, with the benefits of cost savings. And whether you are looking to deploy your first turnkey desalinization treatment plant or to upgrade aging facilities, Aquatron is available to meet your needs.

Waste Water Systems

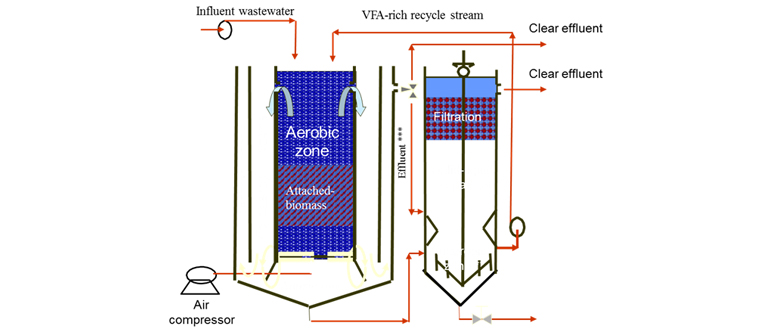

In addition, our new AquaCAST technology is an efficient, cost-effective and environment-friendly technology for the treatment of wastewater, contaminated groundwater and landfill leachate. The target market for the AquaCAST technology consists of municipal applications, industrial operations that produce wastewaters as well as

environmental organizations that are involved in groundwater decontamination operations.

The AquaCAST technology has been designed for the high-rate treatment of industrial wastewater, contaminated groundwater and, municipal effluents. The AquaCAST technology combines a unique configuration of known biological and physical-chemical processes to achieve an efficient, high-rate biological treatment that provides cost effective removal of organic and inorganic contaminants and the production of a fully-treated clear effluent. The contaminants include carbonaceous material, nitrogen and phosphorus compounds as well as hazardous compounds such as phenols and hydrocarbons.

AquaCAST is a highly effective, economical and odorless wastewater technology that generates up to 60% less sludge,has 30% lower energy/electricity consumption, and reduces greenhouse gas generation.

Value Proposition

- Simplified Tertiary Treatment System

- Full Nutrient removal (Simultaneous removal of carbon, nitrogen and phosphorus

- Microbial diversity

- High tolerance to organic load and toxic shock

- 20 %– 30% Lower capital costs

- Up to 60% Lower operation costs

- 40%-60%) lower solids handling and disposition

- Smaller footprint

- Lower maintenance requirements

- Less chemical and energy use